The lightning arrester protects the electrical equipment from lightning. It is placed very near to the equipment and when the lightning occurs the arrester diverts the high voltage wave of lightning to the ground. The selection of arrester depends on the various factors like voltage, current, reliability, etc. The lightning arrestor is mainly classified into twelve types. These types are;

- Road Gap Arrester

- Sphere Gap Arrester

- Horn Gap Arrester

- Multiple-Gap Arrester

- Impulse Protective Gap

- Electrolytic Arrester

- Expulsion Type Lightning Arrester

- Valve Type Lightning Arresters

- Thyrite Lightning Arrester

- Auto valve Arrester

- Oxide Film Arrester

- Metal Oxide Lightning Arresters

Their types are explained below in details.

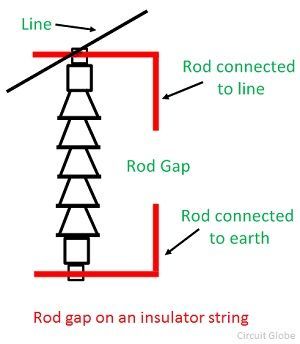

1. Rod Gap Arrester

It is one of the simplest forms of the arrester. In such type of arrester, there is an air gap between the ends of two rods. The one end of the arrester is connected to the line and the second end of the rod is connected to the ground. The gap setting of the arrester should be such that it should break before the damage. When the high voltage occurs on the line, the gap sparks and the fault current passes to the earth. Hence the equipment is protected from damage.

The difficulty with the rod arrester is that once the spark having taken place it may continue for some time even at low voltages. To avoid it a current limiting reactor in series with the rod is used. The resistance limits the current to such an extent that it is sufficient to maintain the arc. Another difficulty with the road gap is that the rod gap is liable to be damaged due to the high temperature of the arc which may cause the rod to melt.

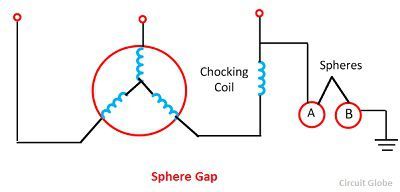

2. Sphere Gap Arrester

In such type of devices, the air gap is provided between two different spheres. One of the spheres is connected to the line, and the other sphere is connected to the ground. The spacing between the two spheres is very small. A choking coil is inserted between the phase winding of the transformer and spheres is connected to the line.

The air gap between the arrester is set in such a way so that the discharge must not take place at normal operating condition.The arc will travel up the sphere as the heated air near the arc tend to rise upward and lengthening till it is interrupted automatically.

3. Horn Gap Arrester

It consists of two horns shaded piece of metal separated by a small air gap and connected in shunt between each conductor and earth. The distance between the two electrodes is such that the normal voltage between the line and earth is insufficient to jump the gap. But the abnormal high voltage will break the gap and so find a path to earth.

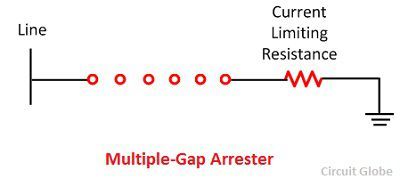

4. Multiple- Gap Arrester

The multiple gap arrester consists a series of small metal cylinder insulated from one another and separated by an air gap. The first and the last of the series is connected to ground. The number of gaps required depends on the line voltage.

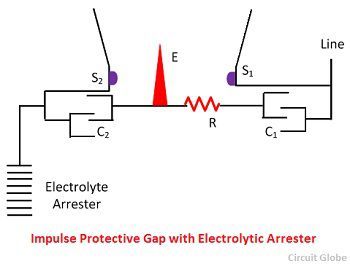

5. Impulse Protective Gap

The protective impulse gap is designed to have a low voltage impulse ratio, even less than one and to extinguish the arc. Their working principle is very simple as shown in the figure below. It consists of two sphere electrode S1 and S2 which are connected respectively to the line and the arrester.

The auxiliary needle is placed between the mid of two sphere S1 and S2. At normal frequency, the impedance of the capacitance C1 is quite large as compared to the impedance of resistor R. If C1 and C2 are equal the potential of the auxiliary electrode will be midway between those of the S1 and S2 and the electrode has no effect on the flash over between them.

When the transient occurs the impedance of capacitor C1 and C2 decrease and the impedance of the resistor now become effective. Due to this, the whole of the voltage is concentrated across the gap between E and S1. The gap at once breakdown, the rest of the length between E and S2 immediately follow.

6. Electrolyte Arrester

In such type of arrester have high a large discharge capacity. It operates on the fact that the thin film of aluminium hydroxide deposits on the aluminium plates immersed in the electrolyte. The plate acts as a high resistance to a low value but a low resistance to a voltage above a critical value.

Voltage more than 400 volts causes a puncture and a free flow of current to earth. When the voltage remains its normal value of 440 volts, the arrester again offers a high resistance in the path and leakage stops.

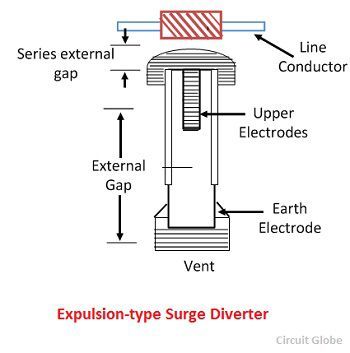

7. Expulsion Type Lightning Arrester

Expulsion type arrester is an improvement over the rod gap in that it seals the flow of power frequency follows the current. This arrester consists of a tube made up of fibre which is very effective, isolating spark gap and an interrupting spark gap inside the fibre tube.

During operation, the arc due to the impulse spark over inside the fibrous tube causes some fibrous material of the tube to volatile in the form of the gas, which is expelled through a vent from the bottom of the tube. Thus, extinguishing the arc just like in circuit breakers.

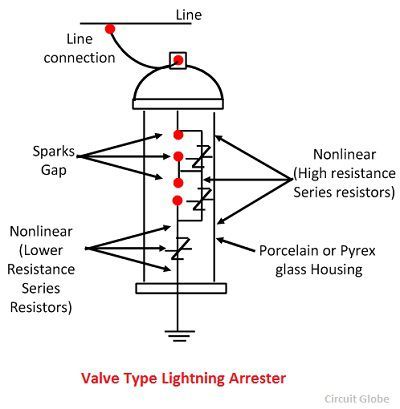

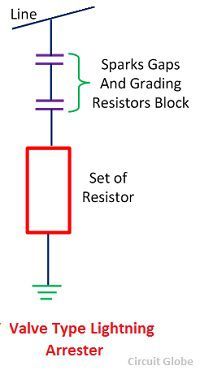

8. Valve Type Lightning Arrester

Such type of resistor is called nonlinear diverter. It essentially consists a divided spark gap in series with a resistance element having the nonlinear characteristic.

The divided spark gap consists of some identical elements coupled in series. Each of them consists two electrodes with the pre-ionization device. Between each element, a grading resistor of high ohmic value is connected in parallel.

During the slow voltage variations, there is no sparks-over across the gap. But when the rapid change in voltage occurs, the potential is no longer evenly graded across the series gap. The influence of unbalancing capacitance between the sparks gaps and the ground prevails over the grounded resistance. The impulse voltage is mainly concentrated on the upper spark gap which in spark over cause the complete arrester to spark over to.

9. Thyrite Lightning Arrester

Such type of arrester is most commonly used for the protection against dangerous high voltage. It consists the thyrite which is an inorganic compound of ceramic material. The resistance of such material decreases rapidly from high value to low value and for current from a low value to high value.

It consists a disc whose both the side is sprayed so as to give the electric contact between the consecutive disc. The disc is assembled inside the glazed porcelain container. It is used in conjunction with the container.

When the lightning takes place, the voltage is raised, and breakdowns of the gaps occur, the resistance falls to a very low value, and the wave is discharged to earth. After the surge has passed the thyrite again come back to its original position.

10 Autovalve Arrester

Such type of arrester consists some flat discs of a porous material stacked one above the other and separated by the thin mica rings. The disc material is not homogenous and conducting material also have been added. Therefore the glow discharge occurs in the capillaries of the material and voltage drop to about 350 volts per unit. The discs are arranged in such a way that normal voltage may not cause a discharge to occur.

11. Oxide Film Arrester

It consists of pellets of lead peroxide with a thin, porous coating of litharge arranged in a column and enclosed in a tube of diameter. Out of the two lead, the upper is connected to the line, while the lower is connected to the earth. The tube contains a series spark gap.

When an overvoltage occurs an arc passes through the series spark gap and an additional voltage is applied to the pellet column and a discharge takes place. After the discharge, the resistance of the pellet gun increases till only very small current flow through it. This small current is finally interrupted by the series spark gaps.

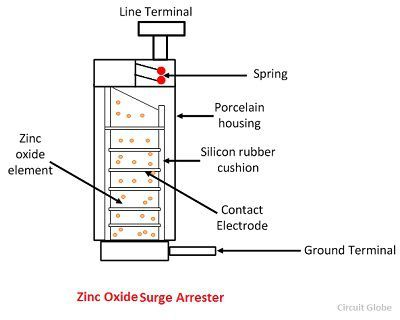

12. Metal Oxide Lightning Arrester

Such Types of diverter are also known as gapless surge diverters, or Zinc oxide diverter. The base material used for manufacturing metal oxide resistor is zinc oxide. It is a semiconducting N-type material. The material is doped by adding some fine power of insulating oxides. The powder is treated with some processes and then it is compressed into a disc-shaped. The disc is then enclosed in a porcelain housing filled with nitrogen gas or SF6.

This arrester consists a potential barrier at the boundaries of each disc of ZNO. This potential barrier controls the flow of current. At normal operating condition, the potential barrier does not allow the current to flow. When an overvoltage occurs, the barrier collapse and sharp transition from insulating to conducting take place. The current start flowing and the surge is diverted to ground.

Please, do we have 330KV Lightning Arresters, if yes, how much?

Thank you.

for 11kv GOD / DO unit with 250KVA, 11kv/433v oil trafo, which class of surge arrestor should be used

Station class or distribution class

what is the price difference between the two class.

Well explained and clear