Definition: The different types of structure (poles or towers) used for supporting the overhead lines or wires, such types of structures are called line supports. The line support plays a major role in power transmission. It kept the proper spacing between the conductors and maintained the conductor at the prescribed distance from its ground parts. It also maintained the specified ground clearance. These clearances are decided by the electrical and mechanical considerations.

Types of Line Supports

The main requirement of the line supports is low cost, low maintenance expense and long life. The line supports are made up wood, concrete, steel or aluminium. It is mainly classified into two types;

- Electrical Pole

- Electrical Tower

Their types are explained below in details.

1. Electrical Pole

A pole which is used for supporting the small voltage (not more than 115 kV) transmission lines, such type of pole is called electrical pole. It is usually made up of woods, concrete or steel. These poles are mainly classified into three types. Their types are explained below in details;

Types of Electrical Poles

The choice of electrical poles depends on the cost, atmosphere, and line voltage of the line.The electrical poles are mainly classified into following types.

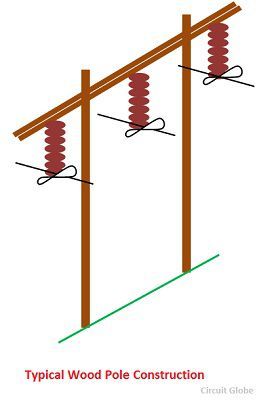

a. Wood Poles

It is one of the cheapest types of line supports and used for lines where spans are short, and tension is low. The wood poles have the limitations of height and diameter. The double pole structure of the A or H types is used where greater strength is required.

The strength of these types of constructions varies from two to four times the strength of the single pole. H-type of construction is usually employed for four terminal poles or those carrying switchgear and transformers.

Wood pole has a natural insulating property, and lesser flashovers are likely to take place due to lightning. One of the drawbacks of wood poles is that their strength and durability cannot be predicted with certainty.

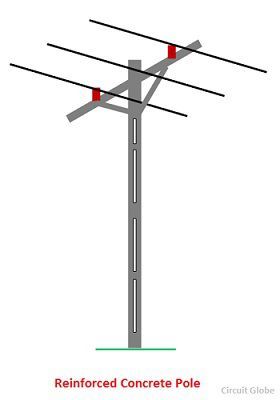

b. Concrete Poles

Concrete pole gave greater strength and used in place of a wood pole. It has a longer life than that of a wood pole because of little degradation. Their maintenance cost is low. Concrete poles are very heavy and are liable to damage during loading, unloading, transportation and erection due to their brittle nature.

Handlings and transportation difficulties are overcome by the use of pre-stressed concrete supports which can be manufactured in pieces and then assembled at the job sites. The weight of pre-stressed concrete poles is more durable than any other type of pole. The material used is less, and it is more durable than any other types of poles.

c. Steel Poles

For low and medium voltage tubular steel poles or Grider steel supports are used. Longer spans are possible with steel poles. The poles need to be galvanised or painted periodically to prevent them from corrosion. Their maintenance expense is high.

2. Electrical Towers

The electrical tower is defined as the tower which is used for carrying the high voltage (above 230 kV) transmission lines. Such types of towers are made up aluminium or steel which gives them strength for supporting the heavy electrical conductor. The electrical towers are broadly classified into various types. These types are explained below.

Types of Supporting Towers

High voltage and extra high voltage lines require large air and ground clearances. They have large mechanical loading and insulation costs. Such types of towers used very long spans. The long-span construction cuts the insulation cost considerably as fewer supports are to be provided. Such types of towers are either made up of steel or aluminium and hence the possibilities of breakdown are reduced. These are classified as

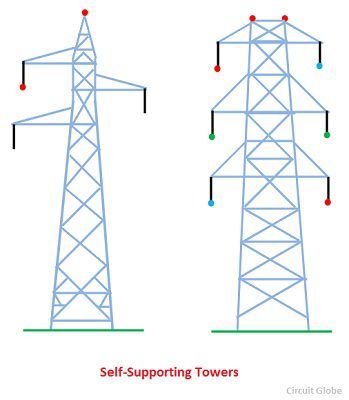

a. Self- Supporting Towers

Self-supporting towers are divided into two categories; wide-base and narrow-base towers. In the wide base tower, lattice (criss-cross) with the roasted connection is adopted. Each leg has a separate foundation. The narrow-base designs used as a lattice (criss-cross) construction of angle, channel or tubular steel section with bolted or welded connection. Self-supporting tower is also classified as

- Tangent Tower – It is used for a straight run of the line. Suspension insulators are used with these towers.

- Deviation Tower – It is used in a line where the transmission line changes direction.

Strain insulators are used with these towers. They have a broader base, stronger members and are costlier as compared to tangent towers. The narrow-based design requires less steel or aluminium in comparison with a wide base tower, but its cost of foundation is more. The selection between the two is based on the costs of material, foundations, and right-of-way requirement.

Strain insulators are used with these towers. They have a broader base, stronger members and are costlier as compared to tangent towers. The narrow-based design requires less steel or aluminium in comparison with a wide base tower, but its cost of foundation is more. The selection between the two is based on the costs of material, foundations, and right-of-way requirement.

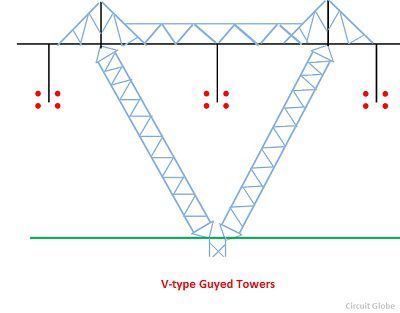

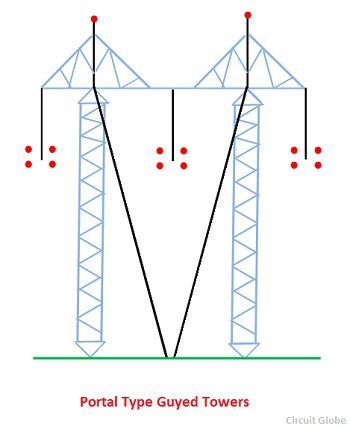

b. Guyed or Stayed Towers

Such types of towers are either portal types or V-types. Both of them had two supports connected at the top by a cross arm and provided with four guys.

In portal structure, each supports is resting on its foundation, whereas in V-support structure the two supports are resting at an angle to one another on one thrust footing only which is of heavier of type.

In portal structure, each supports is resting on its foundation, whereas in V-support structure the two supports are resting at an angle to one another on one thrust footing only which is of heavier of type.

what is electrical pole – Type “A3”

thanks

nice