A Double Cage Induction motor is that type of motor in which a double cage or two rotor windings or cages are used. This arrangement is used for obtaining high starting torque at a low value of starting current. The stator of a double cage rotor of an induction motor is the same as that of a normal induction motor. In the double cage rotor of an induction motor, there are two layers of the bars.

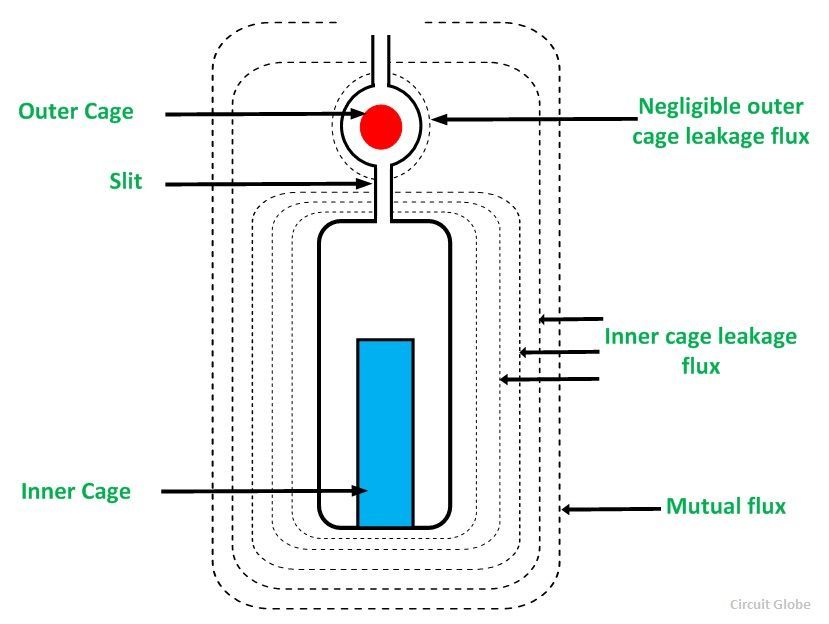

The figure of the double cage induction motor is shown below:

Each layer is short-circuited by the end rings. The outer cage bars have a smaller cross-sectional area than the inner bars and are made of high resistive materials like brass, aluminium, bronze, etc. the bars of the inner cage is made of low resistance copper. Thus, the resistance of the outer cage is greater than the resistance of the inner cage.

There is a slit between the top and the bottom slots. The slit increases linking the inner cage winding as much as larger than that of the outer cage winding. Thus, the inner winding has a greater self-inductance.

At starting, the voltage induced in the rotor is the same as the supply frequency that is (f2 = f1). Hence, the leakage reactance of the inner cage winding as compared to that of the outer cage winding is much larger. The outer cage winding carries most of the starting current which offer low impedance to the flow of current. The high resistance outer cage winding, therefore, develops a high starting torque.

As the rotor speed increases, the frequency of the rotor EMF (fr =sf) decreases. At normal operating speed, the leakage reactance of both the windings become negligibly small. The current in the rotor divides between the two cages and is governed by their resistances. The resistance of the outer cage is about 5 to 6 times that of the inner cage. Hence, the torque of the motor developed mainly by the low resistance inner cage and is developed under normal operating speed.

For the low starting torque requirements, an ordinary cage motor is used. For higher torque requirements a deep bar cage motor is used. A double cage motor is used for higher torques. The slip ring construction is used for large sized motors. The starting torque and the starting periods are also large.

very good

Pls upload more information about Double cage induction motor