Definition: The measurement error is defined as the difference between the true or actual value and the measured value. The true value is the average of the infinite number of measurements, and the measured value is the precise value.

Types of Errors in Measurement

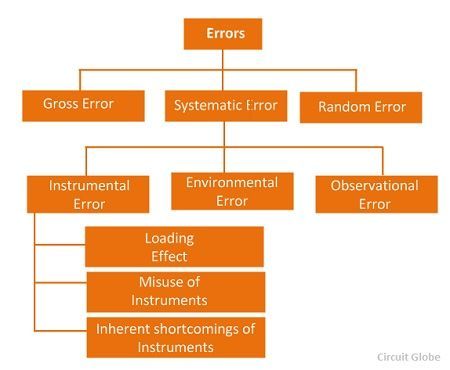

The error may arise from the different source and are usually classified into the following types. These types are

- Gross Errors

- Systematic Errors

- Random Errors

Their types are explained below in details.

1. Gross Errors

The gross error occurs because of the human mistakes. For examples consider the person using the instruments takes the wrong reading, or they can record the incorrect data. Such type of error comes under the gross error. The gross error can only be avoided by taking the reading carefully.

For example – The experimenter reads the 31.5ºC reading while the actual reading is 21.5Cº. This happens because of the oversights. The experimenter takes the wrong reading and because of which the error occurs in the measurement.

Such type of error is very common in the measurement. The complete elimination of such type of error is not possible. Some of the gross error easily detected by the experimenter but some of them are difficult to find. Two methods can remove the gross error.

Two methods can remove the gross error. These methods are

- The reading should be taken very carefully.

- Two or more readings should be taken of the measurement quantity. The readings are taken by the different experimenter and at a different point for removing the error.

2. Systematic Errors

The systematic errors are mainly classified into three categories.

- Instrumental Errors

- Environmental Errors

- Observational Errors

2 (i) Instrumental Errors

These errors mainly arise due to the three main reasons.

(a) Inherent Shortcomings of Instruments – Such types of errors are inbuilt in instruments because of their mechanical structure. They may be due to manufacturing, calibration or operation of the device. These errors may cause the error to read too low or too high.

For example – If the instrument uses the weak spring then it gives the high value of measuring quantity. The error occurs in the instrument because of the friction or hysteresis loss.

(b) Misuse of Instrument – The error occurs in the instrument because of the fault of the operator. A good instrument used in an unintelligent way may give an enormous result.

For example – the misuse of the instrument may cause the failure to adjust the zero of instruments, poor initial adjustment, using lead to too high resistance. These improper practices may not cause permanent damage to the instrument, but all the same, they cause errors.

(c) Loading Effect – It is the most common type of error which is caused by the instrument in measurement work. For example, when the voltmeter is connected to the high resistance circuit it gives a misleading reading, and when it is connected to the low resistance circuit, it gives the dependable reading. This means the voltmeter has a loading effect on the circuit.

The error caused by the loading effect can be overcome by using the meters intelligently. For example, when measuring a low resistance by the ammeter-voltmeter method, a voltmeter having a very high value of resistance should be used.

2 (ii) Environmental Errors

These errors are due to the external condition of the measuring devices. Such types of errors mainly occur due to the effect of temperature, pressure, humidity, dust, vibration or because of the magnetic or electrostatic field. The corrective measures employed to eliminate or to reduce these undesirable effects are

- The arrangement should be made to keep the conditions as constant as possible.

- Using the equipment which is free from these effects.

- By using the techniques which eliminate the effect of these disturbances.

- By applying the computed corrections.

2 (iii) Observational Errors

Such types of errors are due to the wrong observation of the reading. There are many sources of observational error. For example, the pointer of a voltmeter resets slightly above the surface of the scale. Thus an error occurs (because of parallax) unless the line of vision of the observer is exactly above the pointer. To minimise the parallax error highly accurate meters are provided with mirrored scales.

3. Random Errors

The error which is caused by the sudden change in the atmospheric condition, such type of error is called random error. These types of error remain even after the removal of the systematic error. Hence such type of error is also called residual error.

Teacher at a high school in the Caribbean. found the information very informative and easily understood

really good and helpful content. Nice

Super

thank u so much helped with my exam

tq sm it helps a lot and plz explain with diagrams next tym

contents are easily understandable….nice

very good

Really good and helpful content, and

what is meant by pass error in measurements

great… very help full

Excellent! Well elaborated. It helped me a lot with my assignment.

Understable words very nice

Simple, informative and easy to understand. Thank you!

Good very helpful thanks

Thank you for information

THANK YOU SOO MUCH! WITH YOUR HELP EVERYTHING IS POSSIBLE.!

Simple and easy to understand