PLC and DCS are the two automation approaches used for the purpose of controlling processes or machines. Technologically after advancements, the two are not much different nowadays, however, this does not mean that these are not dissimilar. The significant difference between PLC and DCS is that a PLC is a central controller designed with the aim to control processes or machines.

As against, a DCS is a complete system of distributed nature with no central controller but various dispersed controllers offering control to complete system.

PLC stands for Programmable Logic Controller while DCS is an acronym used for the Distributed Control Systems. Here the names are indicating that PLC is a logic controller which is programmed so as to control processes or machines. While DCS is a system consisting of multiple controllers distributed over the plant.

Thus, it can be clearly said that PLC is a part (component) of the system while DCS is as a whole is a system comprising various other elements including PLC.

Content: PLC Vs DCS

Comparison chart

| Basis for Comparison | PLC | DCS |

|---|---|---|

| Basic | PLC is a single unit that discretely controls processes. | DCS is a complete system that control machine operations by carrying out various processes. |

| Year of Invention | 1969 | 1975 |

| Architecture | Simple | Comparatively complex |

| Replaced | Electromechanical relays | Single loop controllers |

| Programmed | According to desired application. | Built-in control functions, configured application-wise. |

| Controls | Machine | Plant (System) |

| Controller type | Centralized (at RTU station) | De-centralized |

| Scan time | 10 milliseconds or less | 100-500 milliseconds |

| Controlling type | Discrete | Regulatory |

| Response time | Fast | Comparatively slow |

| I/O terminals | Less | More |

| Heart of the system | In plc-based system-plc | In DCS-HMI |

| Troubleshooting | Difficult | Easy |

| Human interaction | Minimum | Comparatively more |

| Initial cost | Not expensive | Expensive |

| Flexibility | Less | Comparatively more |

| Utilized for | Dedicated processes | Complex processes |

Definition of PLC

PLC is an electronic device based on a microprocessor that performs the controlling of various processes. The process controlling involves various function implementation like logical operations, counting, sequencing, timing. Also, to achieve this, memory space is required where the plc stores instructions.

In industrial applications, PLCs are designed for controlling processes or machines. It is used for handling dedicated processes as it is pre-programmed. Thus, can be used by even operators, without the requirement of a computer programmer always.

PLCs are somewhat similar to computers. However, as computers are designed for calculative and display applications, PLCs are designed for task controlling and industry-specific uses.

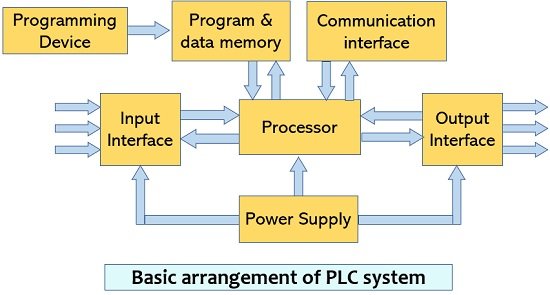

The figure below represents a simplified block diagram of the programmable logic controller:

Like every other system, for a plc also, the CPU is the main element where the microprocessor is programmed to perform required control actions. The power supply energizes the processor by supplying 5V dc input to it along with other peripheral devices.

The memory unit holds the programs which are needed for the control action to take place. However, these programs are needed to be provided to the processor and this task is performed via programming device which is responsible for developing these programs. The input units help to provide user data to the processor while the output units help in displaying the obtained results after processing.

Definition of DCS

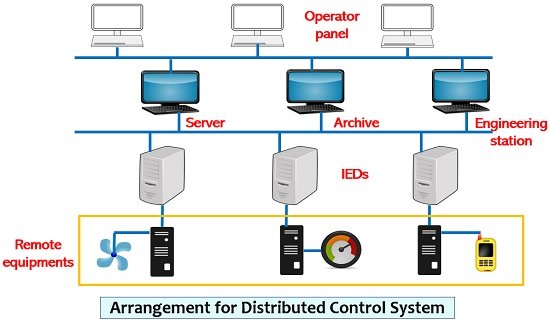

DCS defines systems for controlling processes or plants such as chemical plants, power plants, water management systems, etc. Distributed control systems do so by incorporating various autonomous controllers distributed network-wide. This distributed network does not possess any central supervisory control however, the connection of various controllers is facilitated by high-speed network connectivity.

It involves operator consoles, servers, archiving, and engineering stations along with controllers for process control.

Not only controller, but a DCS involves various intelligent electronic devices (IEDs) dispersed geographically that are programmed to operate in a cooperative way to fulfill the need of the plant. The IEDs can be microcomputers, workstations, etc. The various field devices include sensors, actuators, transmitters, etc.

Key Differences Between PLC and DCS

- The key differentiating factor between PLC and DCS is that a PLC is a single entity designed to control the processes. On the contrary, DCS is a complete system distributed over a large network designed for controlling the whole operation.

- The speed of logic operation also crucially differentiates the two. As PLC is designed to perform high-speed operations, DCS operations are not expected to be that much quicker as it is intended to perform bulk processes.

- PLC is a replacement for electromechanical relay while DCS replaced single loop controllers by including multiple control components.

- The response time of the programmable logic controller is one-tenth of a second (i.e., decisecond) but that of the distributed control system is approximately 30 ms.

- The architecture of PLC is quite simpler than that of DCS.

- The programmable logic controllers are designed for controlling machines such as a lathe machine in which the plc handles the operation of that particular machine.

Whereas the distributed control systems control the complete process like a power system where multiple machine operations are to be handled at various locations. - PLC possesses a centralized controller which is generally present within the RTU. However, there is no centralized controller present in the case of DCS due to distributed network.

- In general, there are less than 1000 I/O ports supported by PLC. While DCS can support several thousands of I/O ports thus are known to be more scalable than PLC.

- The higher scalability of DCS supports their use in process enhancement and data integration. Whereas PLC due to low scalability helps to perform repetitive tasks with reliability.

- The programming of PLC is application-oriented whereas there is a set of built-in control functions with a DCS which is configured according to its various uses.

- The scan time offered by PLC is around 10 milliseconds which is quite less than DCS which provides scan time of 100 to 500 milliseconds.

- PLC offers more difficulty in troubleshooting than DCS due to the reason that issues are more clearly visible in a distributed network than within complex machinery.

- PLCs are comparatively less flexible than DCS in terms of operator accessibility. However, the more flexible nature of DCS leads to chances of exposure to unwanted interference by multiple operators leading to the spurious shutdown.

- The way PLCs are designed makes them usable towards dedicated processes. Whereas the designing of DCSs supports their use in complex processes where frequent adjustments are required to be done.

- PLC involves minimum human interaction whereas there is comparatively more human interaction in DCS.

Conclusion

Thus, it can be concluded that, in a single PLC-based system, if the plc gets damaged then the whole operation gets suspended. But in a DCS, the presence of various independent controllers enables other processes of the system to remain undisturbed so, the plant is not necessarily affected even when one of the controllers gets damaged.

Thank you very much, I really enjoyed the article