Ductility and malleability are the two physical properties associated with stress undertaking the ability of metals. The significant difference between ductility and malleability is that ductility is the result of the application of tensile stress on a metal. As against, the malleability of metal is an outcome of compressive stress applied to it.

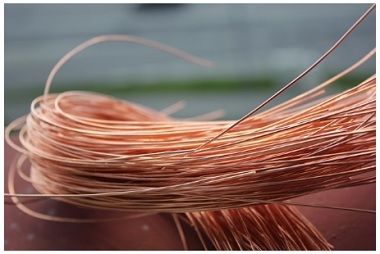

A ductile material when provided with tensile force gets stretched into wires without undergoing cracking or fracturing. However, a malleable material when applied with compressive force then it gets deformed into thin sheets. Both ductility and malleability are the two characteristic properties of metals.

What is Metal?

A substance that possesses high electrical and thermal conductivity and generally has a polished outer surface is known as a metal. The various properties possessed by metals are:

- Hard

- Lustrous

- Malleable

- Ductile

- Sonorous

- Good conductors of heat and electricity

The property of the material (metal) being lustrous corresponds to a shiny appearance. This means metals generally have a radiant surface that reflects light. Another property of a metal that shows its behavior of giving rise to a ringing sound when struck hard or hammered is known as sonorous.

The other two crucial properties of metal i.e., malleability and ductility will be discussed in this content under various differentiating factors.

Content: Ductility Vs Malleability

Comparison Chart

| Basis for Comparison | Ductility | Malleability |

|---|---|---|

| Basic | It corresponds to a change of metal into wires. | It corresponds to a change of metal into sheets. |

| Nature | Stretching | Deforming |

| External stress/force | Tensile | Compressive |

| Changed to | Wires, chains, etc. | Sheets, papers, etc. |

| Measurement | Measured by bend test. | Measured by pressure withstanding ability. |

| Variation in correspondence with each other | The ductile materials show high malleability. | The malleable materials do not necessarily exhibit good ductility. |

| Effect of temperature | Decreases with rise in temperature. | Increases with rise in temperature. |

| Examples | Copper, Bismuth, Nickel, etc. | Gold, Silver, Aluminium, etc. |

Definition of Ductility

Ductility is associated with tensile stress applied to the metals. Tensile stress is basically an application of force at both the ends of the solid material so that the two ends experience pulling away force from each other. So, when tensile stress is applied on a single axis along the length then it can be rolled into wires or chains without having breakage.

Ductility is affected by grain size. This is so because when the particles are smaller then they offer more resistance thus, the motion for disorganization becomes quite difficult. Hence, this decreases ductility. But when the grain size is large then ductility is more.

In the bend test for ductility, the sample is twisted till the time it breaks. As alloys have structural impurity thus these possess a highly ductile nature.

Definition of Malleability

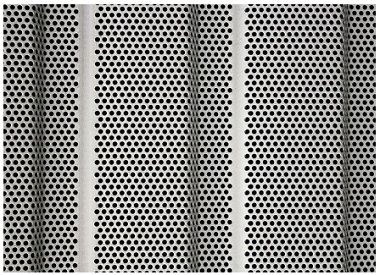

Malleability is associated with compressive stress. A metal when applied with a sufficient amount of compressive stress, changes into thin sheets or papers without breaking.

The arrangement of crystalline structure causes variation in the malleability of the material. Basically, when some force or pressure is applied then the atomic particles must rearrange themselves. This happens in a way that when compressive stress is applied then on the molecular level, the force causes the atom to get roll over each other and attain different positions within the atomic structure without undergoing any breakage.

Due to this, the metal undergoes deformation and its shape changes. Thus, displays the property of malleability.

Key Differences Between Ductility and Malleability

- Ductility is the ability of metals to get stretched under tension without getting damaged in sense of breakage or fracture. On the contrary, malleability is the capacity of metals that shows its behavior of getting flattened under compression without undergoing breakage.

- As stretching is associated with ductility thus as a result of ductile nature the metal is transformed into thin wires. However, as deformation leads to produce a flat surface thus as an outcome of malleable nature the metal is transformed into a thin sheet-like surface.

- The stress that causes the metal to get transformed into wires is of tensile nature. While the stress whose application causes the metal to get transformed into thin sheets is of compressive nature.

- To measure the ductility of metals, a bend test is performed, where the extent up to which the metal can be stretched without fracture is checked. While the malleability of materials is checked by the pressure withholding ability of the metals. Thus, the level of pressure is checked that the metal can sustain without getting fractured.

- Both the properties i.e., ductility and malleability have some effect of temperature change. The increase in temperature causes decrease in the ductility of the material while the rise in temperature, increase the malleability of the material.

- When we talk about their variation with respect to each other then generally, ductile metals exhibit high malleability. Whereas the metals that have high malleability may not possess good ductility.

Conclusion

So, from this discussion, we can conclude that metals significantly display ductility and malleability. Metals like copper, bismuth, aluminium, and nickel, etc. exhibit ductility while metals like gold, silver, and aluminium, etc. possess malleability. However, as we have discussed in this content that ductile materials show high malleability thus, material like aluminium possesses both ductility and malleability.