A starter is a device to start and accelerate a motor. A controller is a device to start the motor, control and reverse the speed of the DC motor and stop the motor. While starting the DC motor, it draws the heavy current which damages the motor.

The starter reduces the heavy current and protects the system from damage.

Need of Starters for DC Motors

The dc motor has no back emf. At the starting of the motor, the armature current is controlled by the resistance of the circuit. The resistance of the armature is low, and when the full voltage is applied at the standstill condition of the motor, the armature current becomes very high which damage the parts of the motor.

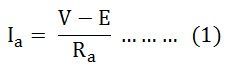

Because of the high armature current, the additional resistance is placed in the armature circuit at starting. The starting resistance of the machine is cut out of the circuit when the machine gains its speeds. The armature current of a motor is given by:

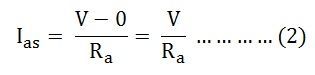

Thus, Ia depends upon E and Ra, if V is kept constant. When the motor is first switched ON, the armature is stationary. Hence, the back EMF Eb is also zero. The initial starting armature current Ias is given by the equation shown below:

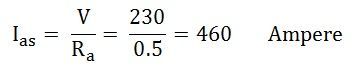

Since, the armature resistance of a motor is very small, generally less than one ohm. Therefore, the starting armature current Ias would be very large. For example – if a motor with the armature resistance of 0.5 ohms is connected directly to a 230 V supply, then by putting the values in the equation (2) we will get,

This large current would damage the brushes, commutator and windings.

As the motor speed increases, the back EMF increases and the difference (V – E) go on decreasing. This results in a gradual decrease of armature current until the motor attains its stable speed and the corresponding back EMF. Under this condition, the armature current reaches its desired value. Thus, it is found that the back EMF helps the armature resistance in limiting the current through the armature.

Since at the time of starting the DC Motor, the starting current is very large. At the time of starting of all DC Motors, except for very small motors, an extra resistance must be connected in series with the armature. This extra resistance is added so that a safe value of the motor is maintained and to limit the starting current until the motor has attained its stable speed.

The series resistance is divided into sections which are cut out one by one, as the speed of the motor rises and the back EMF builds up. The extra resistance is cut out when the speed of the motor builds up to its normal value.

I have a 1897 crocker-wheeler 5 HP DC motor. I need to rebuild a vintage starting rheostat. Need to know what ohms and how many resistors are needed for safe starting? The motor rpm is 900, the amp rating is 38.5.