A breaker which used vacuum as an arc extinction medium is called a vacuum circuit breaker. In this circuit breaker, the fixed and moving contact is enclosed in a permanently sealed vacuum interrupter. The arc is extinct as the contacts are separated in high vacuum. It is mainly used for medium voltage ranging from 11 KV to 33 KV.

Vacuum circuit breaker has a high insulating medium for arc extinction as compared to the other circuit breaker. The pressure inside the vacuum interrupter is approximately 10-4 torrent and at this pressure, very few molecules are present in the interrupter. The vacuum circuit breaker has mainly two phenomenal properties.

- High insulating strength: In comparison to various other insulating media used in circuit breaker vacuum is a superior dielectric medium. It is better than all other media except air and SF6, which are employed at high pressure.

- When an arc is opened by moving apart the contacts in a vacuum, an interruption occurs at the first current zero. With the arc interruption, their dielectric strength increases up to a rate of thousands time as compared to other breakers.

The above two properties make the breakers more efficient, less bulky and cheaper in cost. Their service life is also much greater than any other circuit breaker, and almost no maintenance are required.

Construction of Vacuum Circuit Breaker

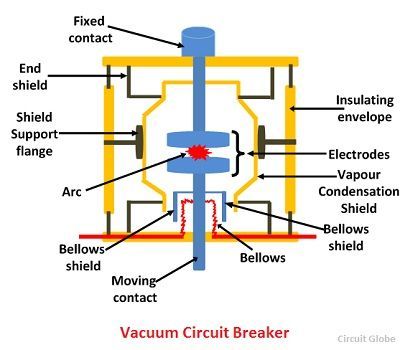

It is very simple in construction as compared to any other circuit breaker. Their construction is mainly divided into three parts, i.e., fixed contacts, moving contact and arc shield which is placed inside the arc interrupting chamber.

The outer envelope of vacuum circuit breaker is made up of glass because the glass envelope help in the examination of the breaker from outside after the operation. If the glass becomes milky from its original finish of silvery mirror, then it indicates that the breaker is losing vacuum.

The outer envelope of vacuum circuit breaker is made up of glass because the glass envelope help in the examination of the breaker from outside after the operation. If the glass becomes milky from its original finish of silvery mirror, then it indicates that the breaker is losing vacuum.

The fixed and moving contacts of the breaker are placed inside the arc shield. The pressure in a vacuum interrupter at the time of sealing off is kept at about 10-6 torr. The moving contacts of the circuit breaker are move through a distance of 5 to 10 mm depending upon the operating voltage.

The metallic bellows made of stainless steel is used to move the moving contacts. The design of the metallic bellows is very important because the life of the vacuum circuit breaker depends on the ability of the component to perform repeated operations satisfactorily.

Working Vacuum Circuit Breaker

When the fault occurs in the system, the contacts of the breaker are moved apart and hence the arc is developed between them. When the current carrying contacts are pulled apart, the temperature of their connecting parts is very high due to which ionization occurs. Due to the ionization, the contact space is filled with vapour of positive ions which is discharged from the contact material.

The density of vapour depends on the current in the arcing. Due to the decreasing mode of current wave their rate of release of vapour fall and after the current zero, the medium regains its dielectric strength provided vapour density around the contacts reduced. Hence, the arc does not restrike again because the metal vapour is quickly removed from the contact zone.

Current Chopping in Vacuum Circuit Breaker

Current chopping in vacuum circuit breaker depends on the vapour pressure and the electron emission properties of the contact material. The chopping level is also influenced by the thermal conductivity–lower the thermal conductivity, lower is the chopping level.

It is possible to reduce the current level at which chopping occurs by selecting a contact material which gives out sufficient metal vapour to allow the current to come to a very low value or zero value, but this is rarely done as it affects the dielectric strength adversely.

Vacuum Arc recovery of Vacuum Circuit Breaker

High vacuum possesses extremely high dielectric strength. At zero current the arc is extinguished very quickly, and the dielectric strength is established very quickly. This return of dielectric strength is because of the vaporized metal which is localized between the contacts diffuses rapidly due to the absence of gas molecules. After arc interruption, the recovery strength during the first few microseconds is 1 kV/µs second for an arc current of 100A.

Because of the above-mentioned attribute of vacuum circuit breaker, it is capable of handling the severe recovery transients associated with short-line faults without any difficulty.

Property of contact material

The contact material of the vacuum circuit breaker should have the following property.

- The material should have high electrical conductivity so as to pass normal load currents without overheating.

- The contact material should have low resistance and high density.

- The material should possess high thermal conductivity so as to dissipate rapidly the large heat generated during arcing.

- The material should have a high arc withstand ability and low current chopping level.

Advantages of Vacuum Circuit Breaker

- Vacuum circuit breaker does not require any additional filling of oil or gas. They do not need periodic refilling.

- Rapid recovery of high dielectric strength on current interruptions that only a half cycle or less arcing occurs after proper contact separation.

- Breaker unit is compact and self-contained. It can be installed in any required orientation.

- Because of the above reasons together with the economic advantage offered, vacuum circuit breaker has high acceptance.

Disadvantage of Vaccum Circuit Breaker

- Requirements of high technology for production of vacuum interrupters.

- It needs additional surge suppressors for the interruption of low magnetizing currents in a certain range.

- Loss of vacuum due to transit damage or failure makes the entire interrupter useless, and it cannot be repaired on site.

Applications of Vacuum Circuit Breaker

- Because of the short gap and excellent recovery of vacuum circuit breaker, they are very useful as very high speed making switches in many industrial applications.

- When the voltage is high and current to be interrupted is low these breakers have definite superiority over the other breakers.

- For low fault interrupting capacities the cost is low in comparison to other interrupting devices.

- Because of the least requirements of maintenance, these breakers are very suitable for the system which requires voltage from 11 to 33 kV

Super it is….Thanku so much CG….i’m very happy

thanks for this info. nice job

This data is really good… I don’t have to search any other sites… Thnx very much for uploading that kind of data….

thanks you

Thanks a lot. This piece is what I needed at the moment.

This is a very good website.

Thanks for the info.