Definition: The system which is used for controlling the motion of an electrical machine, such type of system is called an electrical drive. In other words, the drive which uses the electric motor is called electrical drive. The electrical drive uses any of the prime movers like diesel or a petrol engine, gas or steam turbines, steam engines, hydraulic motors and electrical motors as a primary source of energy. This prime mover supplies the mechanical energy to the drive for motion control.

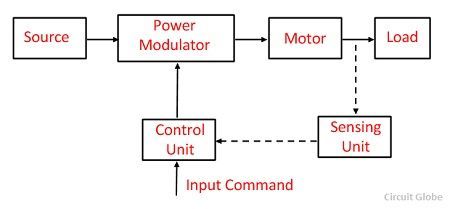

The block diagram of the electrical drive is shown in the figure below. The electrical load like fans, pumps, trains, etc., consists the electrical motor. The requirement of an electrical load is determined regarding speed and torque. The motor which suited the capabilities of the load is chosen for the load drive.

Parts of Electrical Drive

Parts of Electrical Drive

The main parts of the electrical drives are power modulator, motor, controlling unit and sensing units.Their parts are explained below in details.

Power Modulator – The power modulator regulates the output power of the source. It controls the power from the source to the motor in such a manner that motor transmits the speed-torque characteristic required by the load. During the transient operations like starting, braking and speed reversing the excessive current drawn from the source. This excessive current drawn from the source may overload it or may cause a voltage drop. Hence the power modulator restricts the source and motor current.

The power modulator converts the energy according to the requirement of the motor e.g. if the source is DC and an induction motor is used then power modulator convert DC into AC. It also selects the mode of operation of the motor, i.e., motoring or braking.

Control Unit – The control unit controls the power modulator which operates at small voltage and power levels. The control unit also operates the power modulator as desired. It also generates the commands for the protection of power modulator and motor. An input command signal which adjusts the operating point of the drive, from an input to the control unit.

Sensing Unit – It senses the certain drive parameter like motor current and speed. It mainly required either for protection or for closed loop operation.

Advantages of Electrical Drive

The following are the advantages of electrical drive.

- The electric drive has very large range of torque, speed and power.

- Their working is independent of the environmental condition.

- The electric drives are free from pollution.

- The electric drives operate on all the quadrants of speed torque plane.

- The drive can easily be started and it does not require any refuelling.

- The efficiency of the drives is high because fewer losses occur on it.

The electric drives have many advantages shown above. The only disadvantage of the drive is that sometimes the mechanical energy produced by the prime mover is first converted into electrical energy and then into a mechanical work by the help of the motor. This can be done by the help of the electrical link which is associated with the prime mover and the load.

Because of the following advantages, the mechanical energy already available from a non-electrical prime mover is sometimes first converted into electrical energy by a generator and back to a mechanical energy of an electrical motor. Electrical link thus provides between the non-electrical prime mover and the load impact to the drive flexible control characteristic.

For example – The diesel locomotive produces the diesel energy by the help of the diesel engine. The mechanical energy is converted into an electrical energy by the help of the generator. This electrical energy is used for driving the other locomotive.

Disadvantages of Electrical Drive

The power failure completely disabled the whole of the system.

- The application of the drive is limited because it cannot use in a place where the power supply is not available.

- It can cause noise pollution.

- The initial cost of the system is high.

- It has a poor dynamic response.

- The output power obtained from the drive is low.

- During the breakdown of conductors or short circuit, the system may get damaged due to which several problems occur.

Application of Electric Drive

It is used in a large number of industrial and domestic applications like transportation systems, rolling mills, paper machines, textile mills, machine tools, fans, pumps, robots and washing, etc.

I like it.

Thanks

nice post. it is really helpful.

thanks

good!!!!

nice i got full marks in my test coz of this

Nice

Please answer – Electric drive strength and limitation

Thnx circuitglobe .com

good piece of article.

Looks a very good over view! Thanks.

very good explanation, thanks.

very precise and comprehensive. thanks

Very Helpful for me.